WD Industrial Group, a Winnipeg manufacturer for the municipal sewer and water industry, had a project started to develop a composite manhole cover with the main objective to significantly reduce the weight. They required composite materials expertise and brought us in to assist with the analysis, testing and prototyping of the new cover.

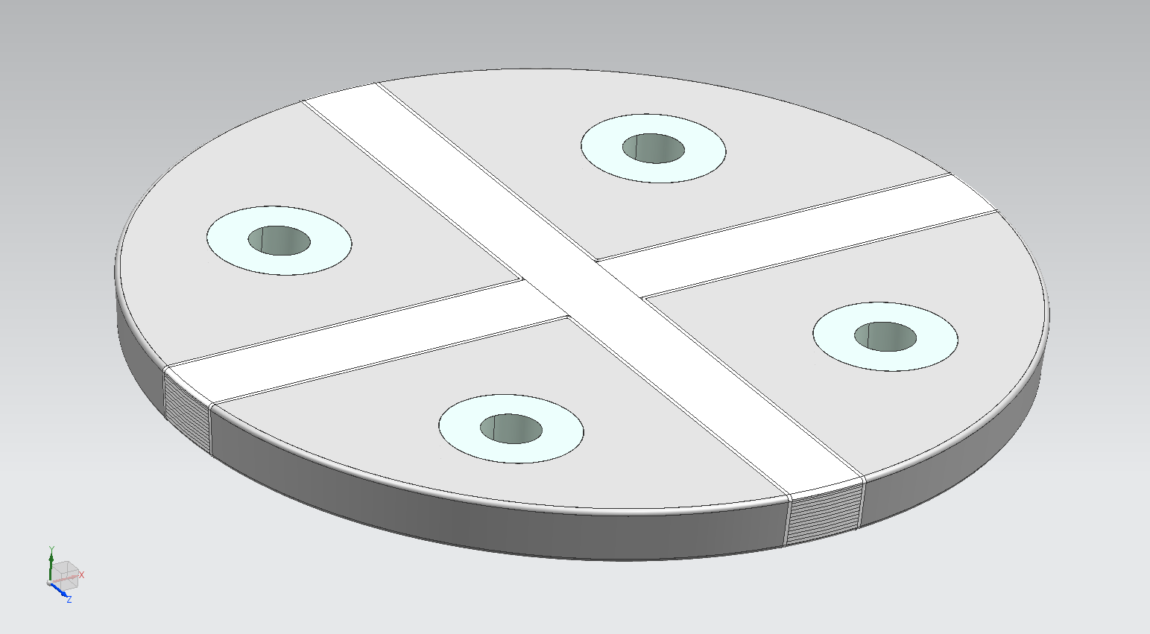

We began with a prototype of the initial design that WD Industrial Group provided and using that prototype we adjusted the CAD models to improve the functionality. The final design included a solid laminate cross in addition to the core material and four urethane inserts. Two of the inserts were to help with lifting the cover and the other two were for the locking mechanisms to be attached.

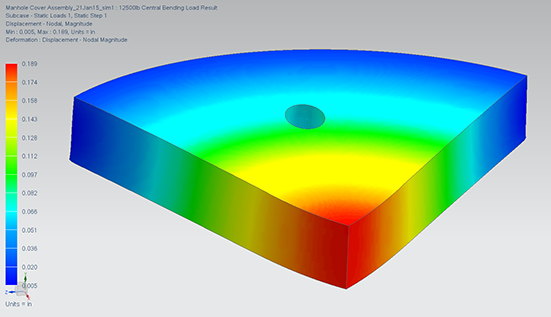

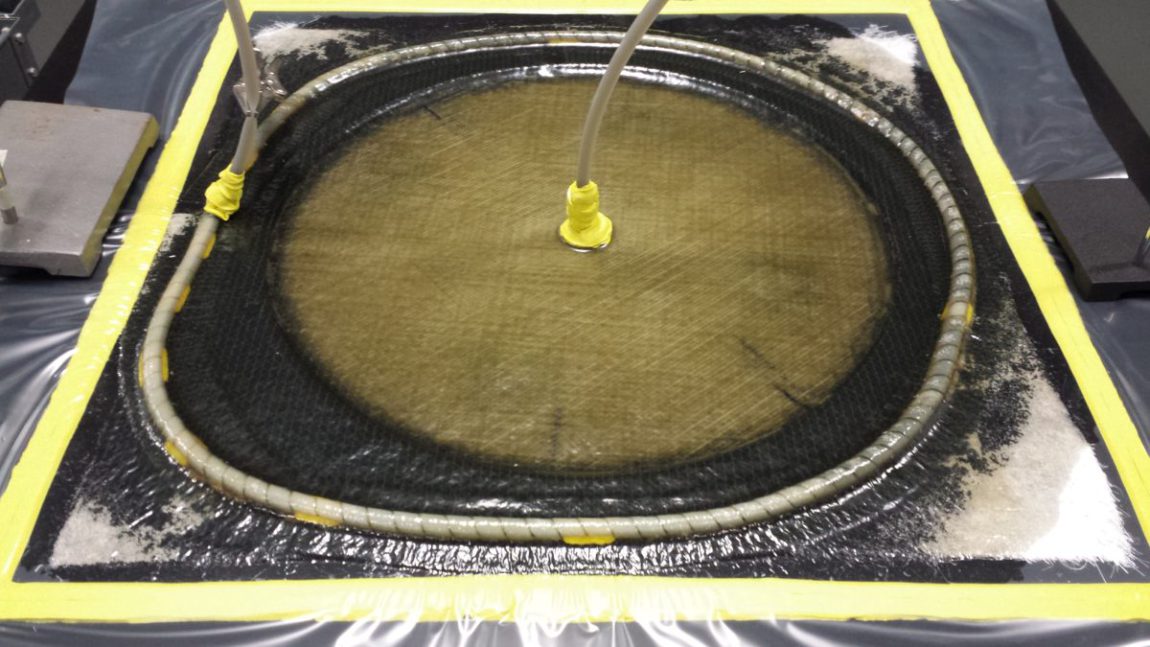

One area of concern was the bond between the urethane inserts and the upper laminate. The manhole cover needed to withstand 50,000 lbs of distributed load and we used our shear testing and analysis capabilities to validate that it would not delaminate. The final step in this project was fabricating a full-scale functional prototype in our shop to verify the updated design and manufacturing method.

The end result for WD Industrial Group was a 40 lbs composite manhole cover with an integrated locking system to ensure the cover would stay secure while in place. With most manhole covers weighing over 200 lbs, this project was a significant success.