CTS Composites (CTS), a supplier of patterns and molds, approached us to perform quality control testing for tools and infused carbon fibre parts that they were manufacturing for a thrill ride client. We were asked to demonstrate that a minimum glass transition temperature for the composite material was achieved. For the tools, this confirms that they wouldn’t change shape during the cure cycle. For the parts, this verifies that they were cured correctly. Our expertise with composites allowed us to support CTS by verifying that the tools and parts being manufactured met the requirements set by their client.

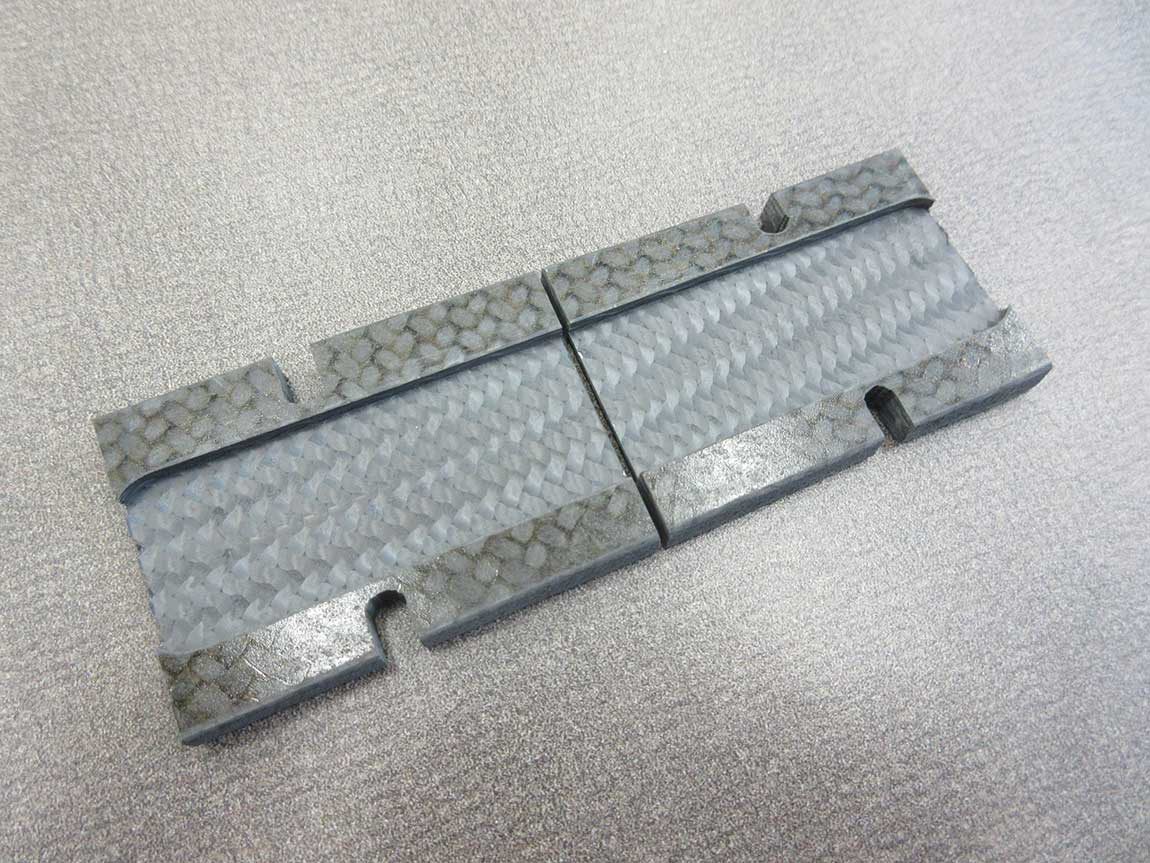

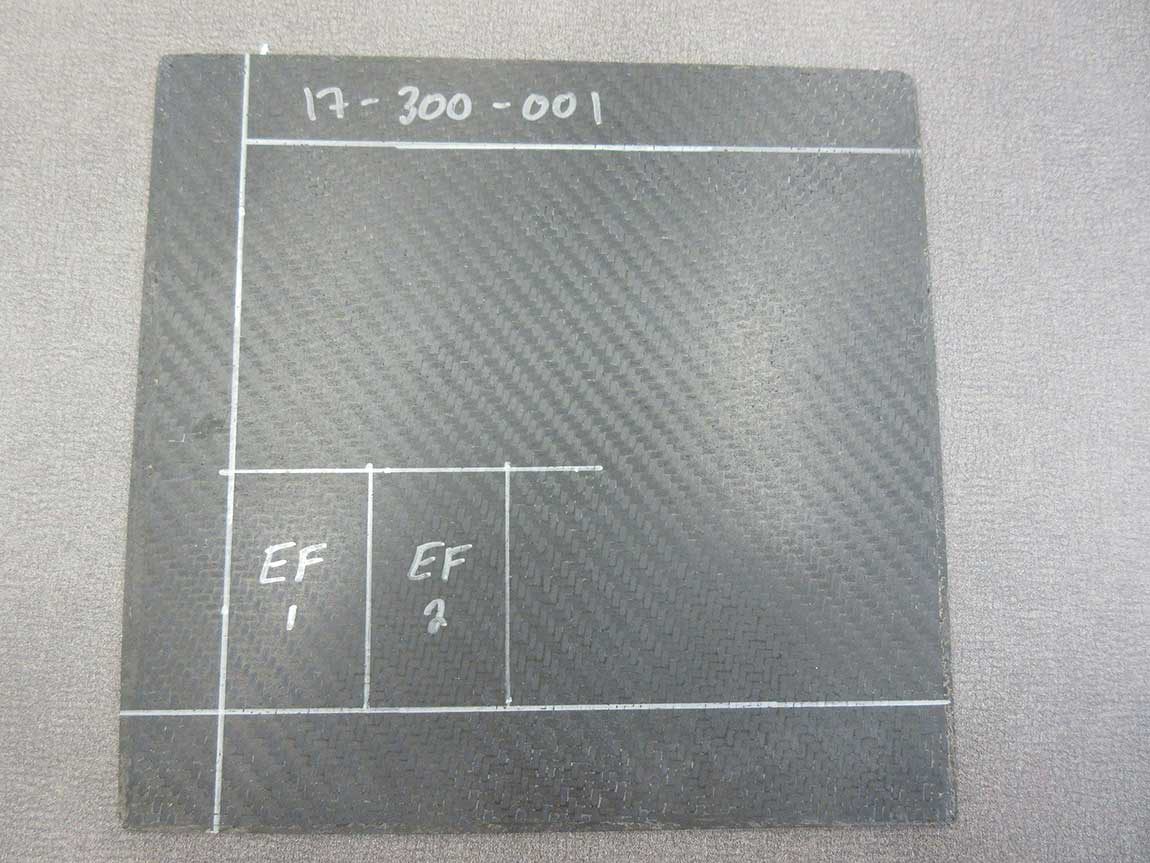

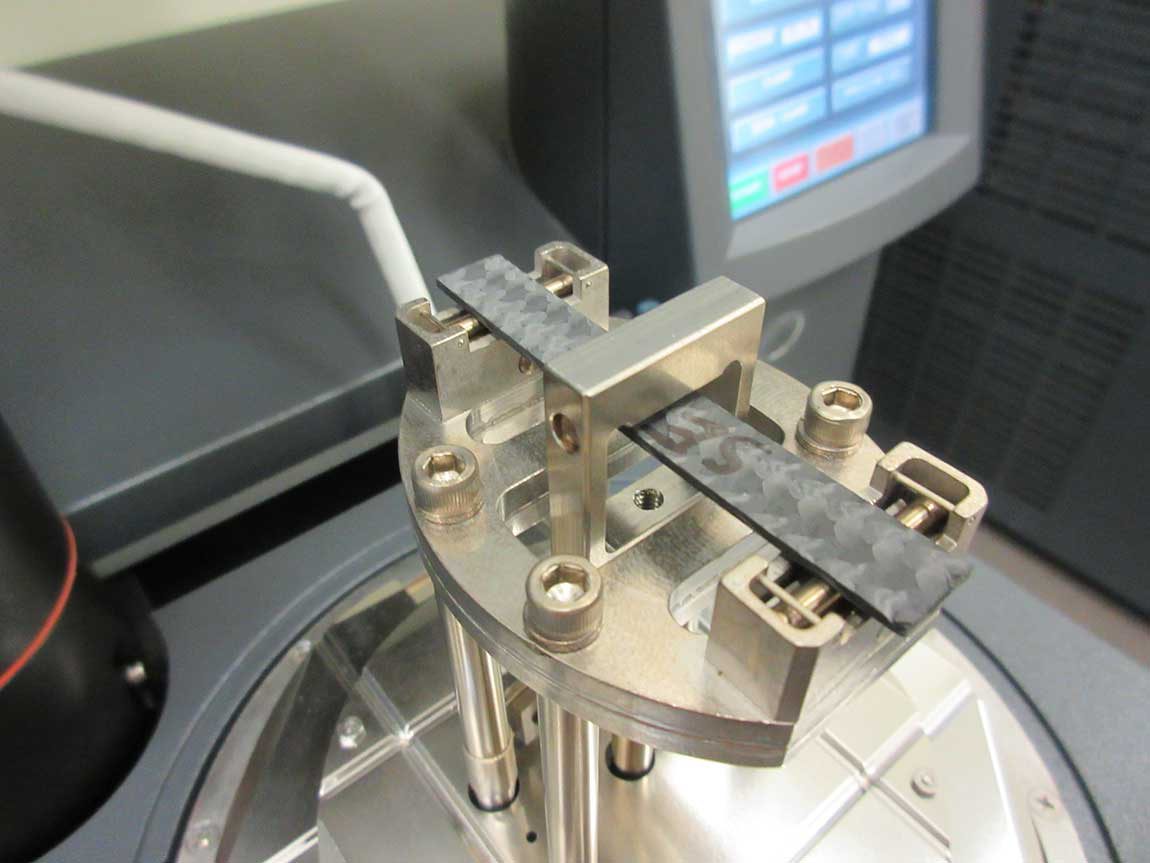

CTS fabricated a traveller coupon with each of the 72 sets of parts made for a thrill ride seat structure. The coupons were sent to our lab for quality control testing. We then prepared the specimens using our diamond wafering saw, and used a dynamic mechanical analyzer (DMA) to evaluate them.

Our clients rely on our extensive experience with testing composite materials and our ability to accurately interpret and communicate the results. If there are any anomalies in the results, we relay this to the client to ensure full transparency and allow them to address any issues that may have caused the anomaly. We were able to accommodate the recurring testing within a tight production schedule to ensure that CTS could deliver the parts on time to their client.