Bionic Power, a technology company based in Vancouver, created an advanced wearable technology that generates electricity from the natural action of walking. A major market for this is with military members when on assignment and they need power to navigate and communicate with their teams. Bionic Power needed our support to commercialize the shells that housed the technology.

We worked with them to develop the lightweight carbon fibre shells to replace the heavy existing shells. They were under a tight timeline and needed assistance with navigating the product development process.

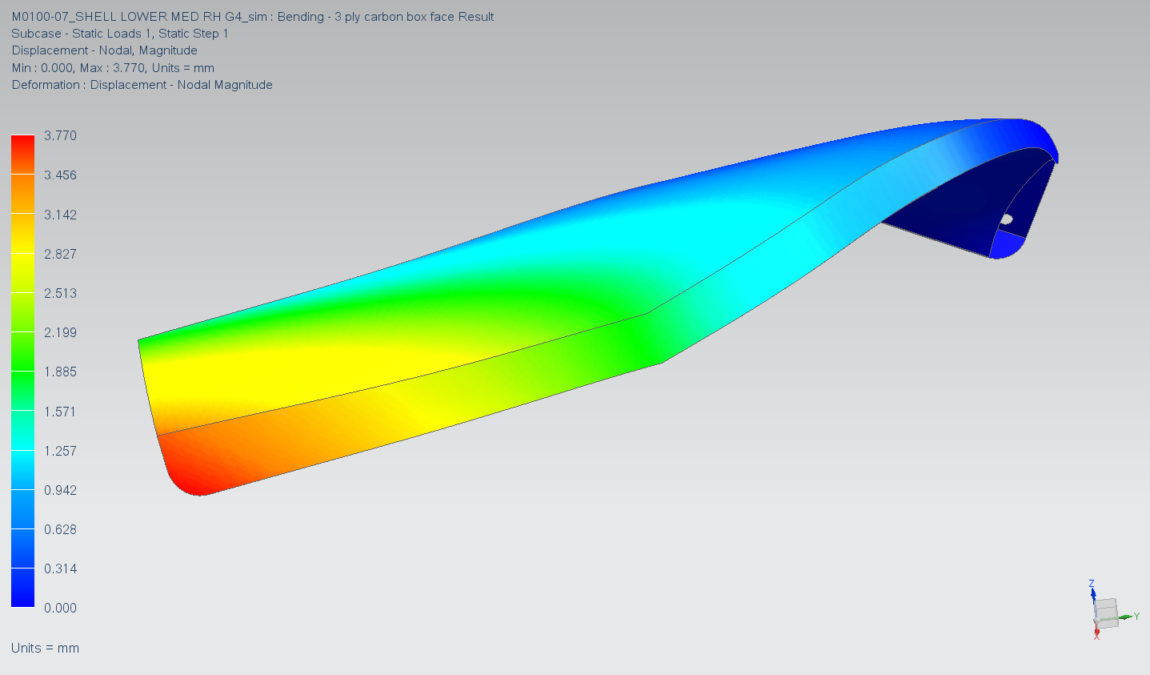

Most of our team was involved on this project as we did the design, analysis, prototyping and the first production run. We started with a feasibility study to determine the best manufacturing process for the carbon fibre material and design. From there we adjusted the provided CAD models of all 4 shells (2 upper leg and 2 lower leg) to make sure they were designed for optimal performance. We also performed analysis to confirm the shells could withstand specified loads such as when a person bends their leg and applies force to the shell or rests the shell on their shin against the frame of a window.

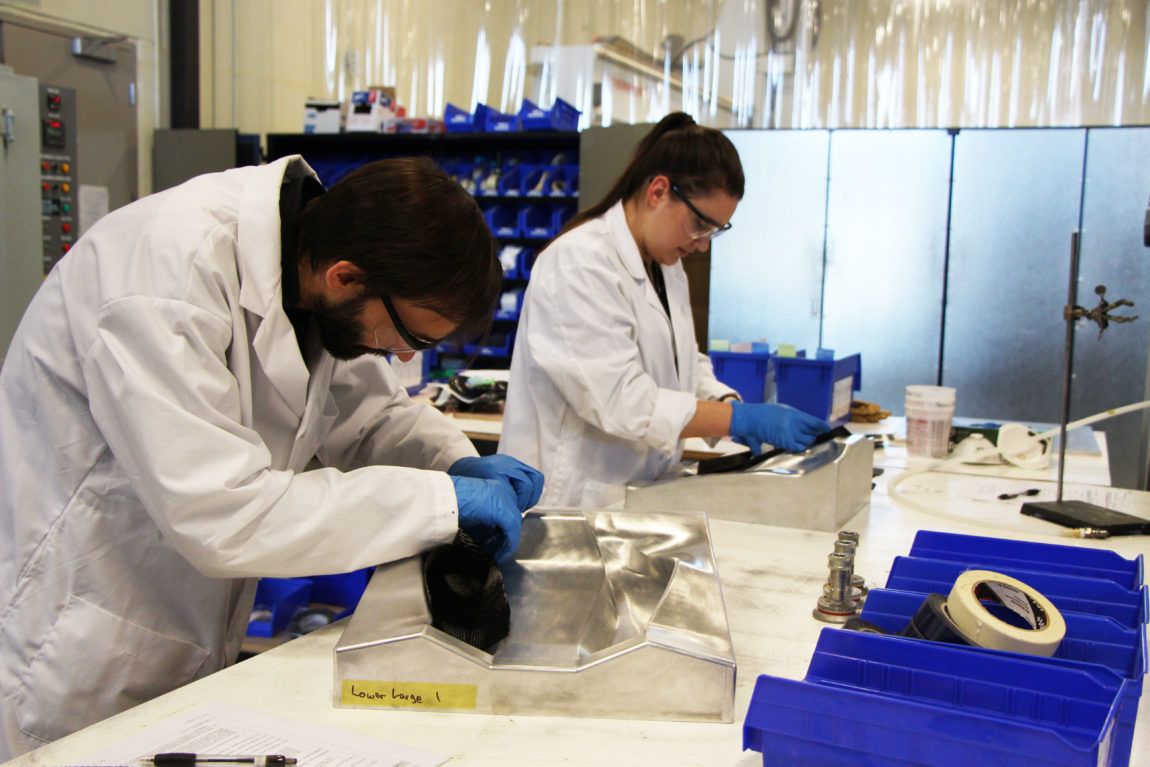

Our next step was to verify the design through prototyping trials to make sure the manufacturing process resulted in parts that met the standards set by Bionic Power. One part of the process we paid close attention to was ensuring the shells would not deform when cured because of the complex shape. Our engineers and fabrication technicians worked closely together to eliminate any potential problems throughout the entire project.

We also manufactured the first production run of over 100 units (4 shells per unit) in our shop on a very short timeline. Bionic had contracts with the U.S. Army and Canadian Forces to deliver units for in-field testing and we helped them meet those deadlines and commercialize their product.