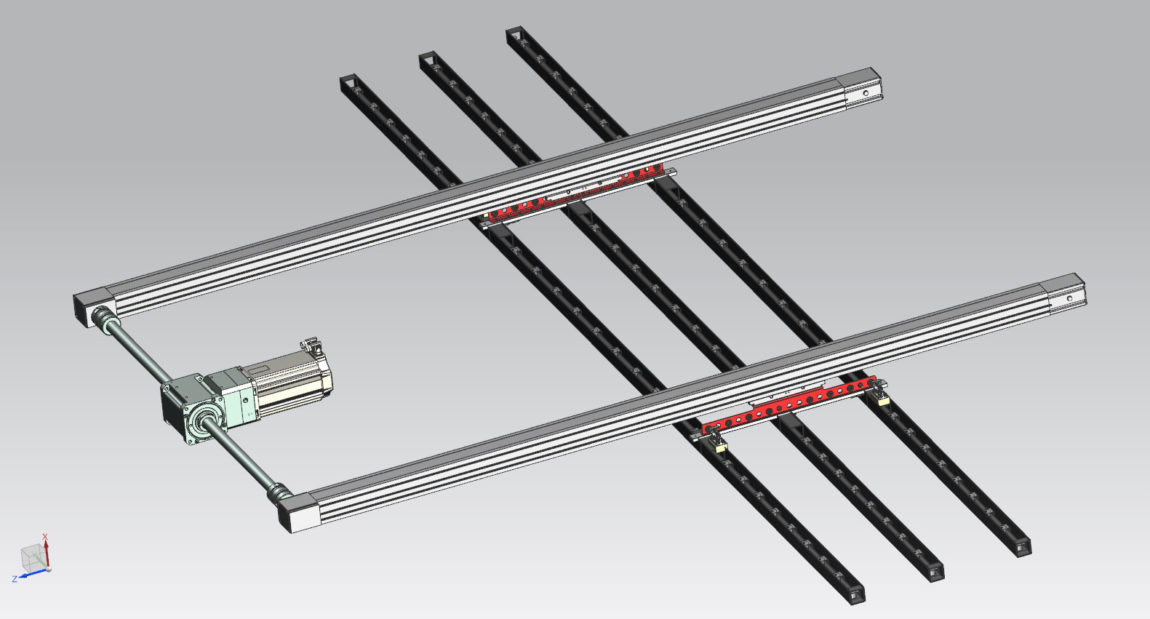

Micro Tool & Machine Ltd. (MTM), a Winnipeg-based custom machinery manufacturer for the electrical transformer industry, needed support to improve their production line. We were brought in to determine if replacing a metallic pick-and-place arm with a composite alternative could increase production capacity from 25 to 50 per cycle.

We assessed the client’s two options with a feasibility study. The first was to replace the servo motor assembly with an expensive and more powerful one; the second was to make the machine’s arms lighter so that the existing servo motor assembly could continue to be used. After reviewing the results, the second option was chosen to keep costs down while maintaining production volumes and minimizing disruptions to their manufacturing process.

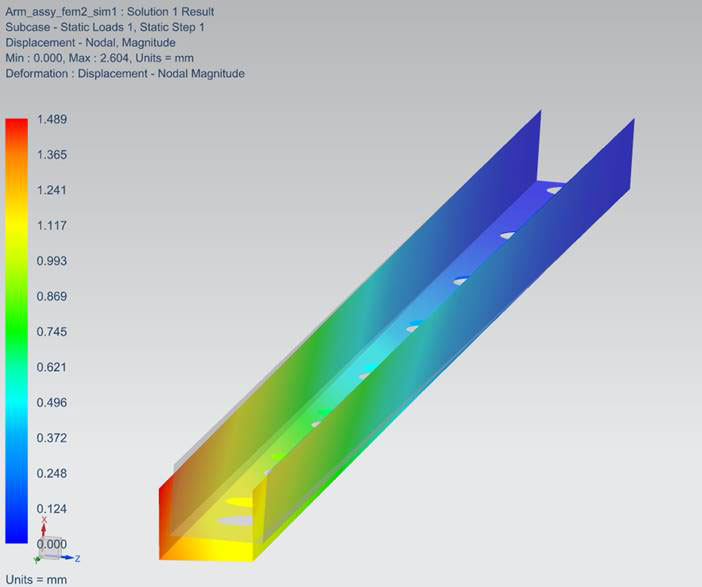

Our Design Team found a composite solution to replace the metallic arm, utilizing an off-the-shelf carbon fibre tube that could be custom machined to suit the client’s needs. To confirm the selected carbon fibre tube would perform better than the existing metallic arm, we analyzed and compared the two; the composite arm was significantly stronger, stiffer and weighed 50% less.

Micro Tool & Machine Ltd. commercialized the arms into their 600 mm Automated Cutting and Stacking Line (XS600-P20) and have been showcasing the new piece of equipment at shows around the world. Prior to working with us, they had little to no experience using composites; they are now looking at replacing other parts in their machines with composite materials to find more weight and cost savings.