Project Feature – Canadian Mat Systems – Tuvvaq Rig Mat

Canadian Mat Systems (CMS) is a leading manufacturer of temporary structural foundation panels, commonly called mats, used to support operational activity in areas of low weight-bearing soil conditions. They approached us to optimize the design and materials for their Tuvvaq Rig Mat to reduce weight, reduce cost and increase longevity while meeting functional requirements.

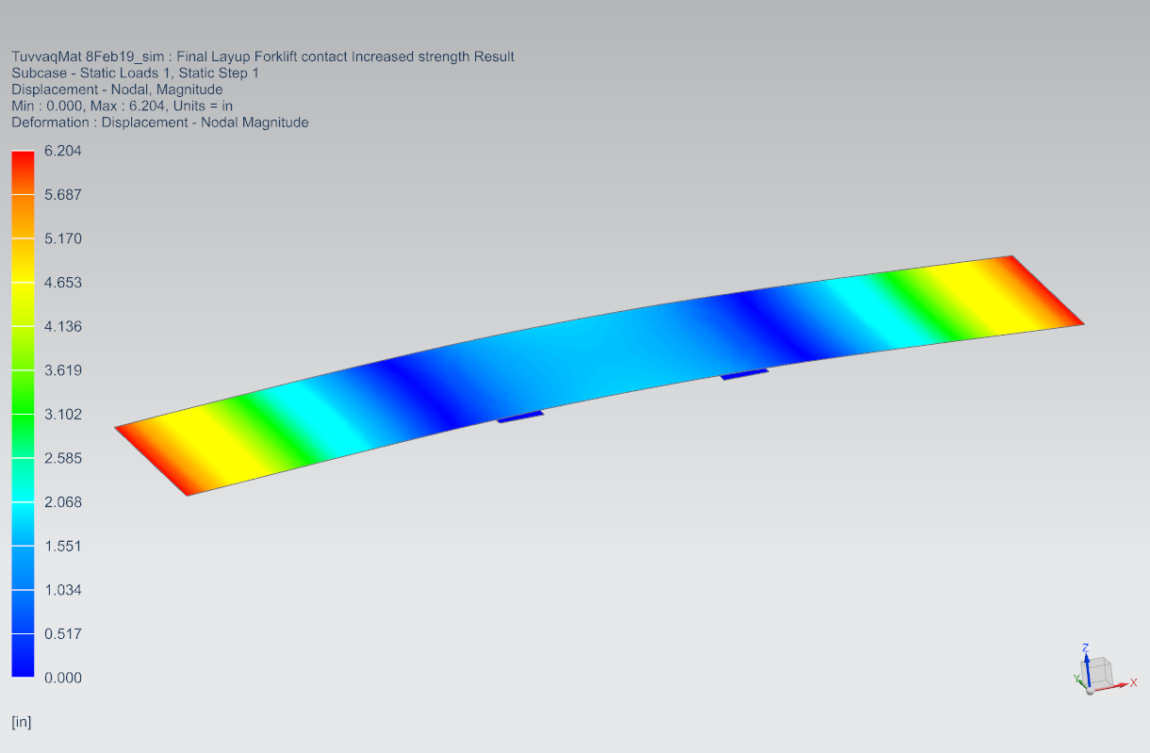

These mats, sized 30 by 8 feet, are used as a temporary surface for heavy equipment, such as drilling rigs weighing as much as several million pounds. They are primarily used in areas with poor weight-bearing soil conditions such as the tundra in Alaska and northwest Canada. CMS also identified the need for the new mat to be engineered with appropriate flexibility to better conform to the soil surface to properly support heavy equipment.

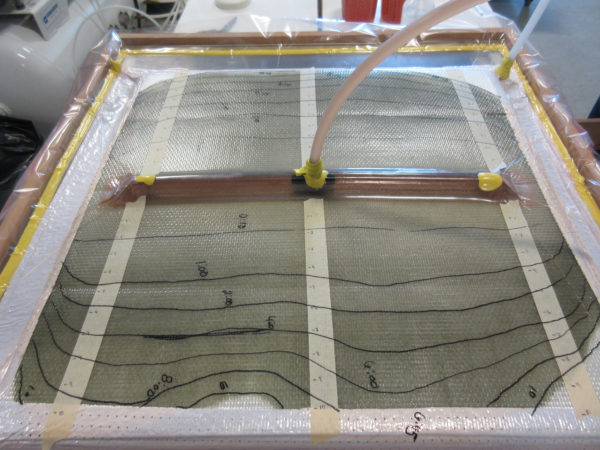

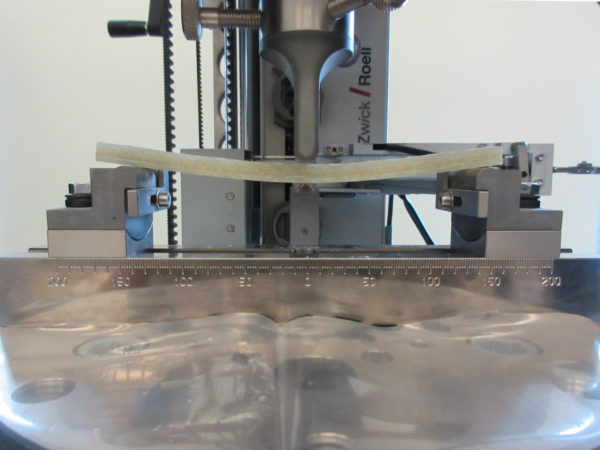

Our Analysis, Testing and Fabrication Teams worked together to deliver a manufacturing-friendly solution for CMS. We completed fabrication trials with multiple materials to verify the design, and performed analysis to determine the best material option for increasing performance while finding weight and cost savings. After the fabrication trials, we did sub-scale flexure testing to confirm the panel properties. The results informed our analysis and supported the scale-up for manufacturing.

We provided guidance to CMS during the initial manufacturing process and developed the associated documentation to make sure the mats were consistently fabricated.

We worked collaboratively with CMS to develop the Tuvvaq 2.0 Rig Mat that is approximately a third lighter than the previous version, costs less to manufacture and has improved functionality. The final product was successfully engineered for safety, environmental protection and longevity in a harsh environment.

Taking Steps in a New Direction

We’ve seen a lot of change lately and are now, more than ever, dedicated to supporting the manufacturing industry. With our value-added integrated engineering services, we support clients from initial concepts through to prototyping and low-volume production.

With our focus mainly on supporting the manufacturing sector, we have some of our R&D equipment available for purchase. Please see the list below:

- Agilent Cary 670 FTIR Spectrometer

- Agilent SuperNova A (Cu) Diffractometer – X-ray Diffractometer System

- Carl Zeiss SEM EVO LS10 – Scanning Electron Microscope

- Carl Zeiss LSM 710 Configuration #6 – Laser Scanning Confocal Microscope

- Carl Zeiss Axio Vert A1 – Inverted Microscope

- Leica EM TIC3X – Triple Ion Beam Milling System

- Leica EM TXP – Target Surfacing System

- Leica Ultracut EM UC7 – Ultramicrotome

- Retsch Ultra Centrifugal Mill ZM200

- Strauch Doublewide Motorized Drum Carder DCM-405x-2

- Surface Measurement Systems DVS Advantage1 – Dynamic Vapour Sorption

- Surface Measurement Systems Inverse Gas Chromatography – Surface Energy Analyzer (iGC-SEA)

Please send all inquiries to techservices@compositesinnovation.ca